Collaborative Care

In collaboration with ABB Robotics

Master Thesis - 20 weeks

Umeå Institute Of Design

2023

Demographic changes are putting the healthcare sector globally under pressure. Aging populations and a rise in chronic diseases have seen a need for more hospital care, which could not be met in nursing capacity. The resulting higher demands to the existing workforce have resulted in a rise of burnout and a low retention rate in the industry. Meanwhile, advancements in robotics have allowed for collaborative robots to work closely with humans, automating repetitive tasks in many industries. However, the healthcare sector is still reluctant to change and is not yet seeing larger-scale implementations of automated processes. This project investigated the problems with the design of medical collaborative robots today, while identifying repetitive and tedious tasks with potential for automation by applying usercentered research methods, and proposes actionable design principles for a successful implementation of robotics in hospitals.

See the 3-minutes pitch from UID23!

When we think of nursing, it is often pictured when nurses are in close contact with their patients, delivering direct care. In reality, other tasks, such as patient documentation and medical administration, consume a significant amount of time, leaving patient assessment and care at only 25%. However, direct care is critical in ensuring good patient outcomes.

Medical administration

20%

Patient documentation &

care coordination

55%

Patient assesment & care

25%

Numbers are rounded.

Source: A 36-Hospital Time and Motion Study: How Do Medical-Surgical Nurses Spend Their Time? (2008)

Furthermore, providing high-quality care demands a lot of physical activity from nurses. Besides suffering from heavy lifting when handling patients, they walk up to 10.000 steps per shift on average - fetching items from around the ward, resupplying goods and visiting patients. Many of these time-consuming chores could be avoided by eliminating repetitive tasks in the ward intra-logistics and human error in the medicine supply chain within a hospital.

Steps per shift on average

10000 Steps

Numbers are rounded.

Nurses’ steps, distance traveled, and perceived physical demands in a three-shift schedule (2022)

„It is almost more unplanned ways than planned.“

To the question: What ways you do during the day could be avoided?

„One hour per day is just fetching things.“

To the question: What makes nurses walk so much?

A mobile, collaborative robot, to take repetitive tasks in restocking and supply of medication out of nurses hands.

Design opportunity

Hej, I am Edward!

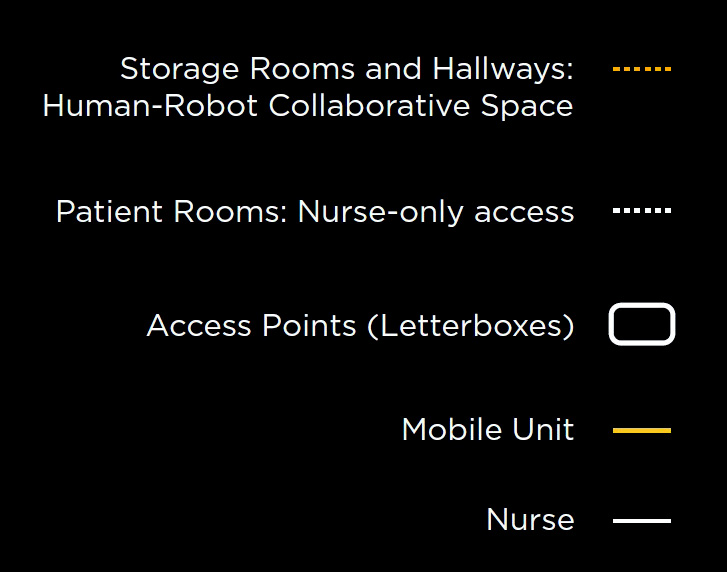

Edward is part of a logistical system consisting of fully autonomous, integrated mobile units and distributed access points, designed to reduces nurses’ time spent on logistical tasks.

↑ The mobile unit connects remote storage rooms to the wards and acts as a porter by continuously monitoring and resupplying medicine and practical goods.

↑ Distributed access points allow for increased efficiency by delivering items without the need for direct interaction between the mobile unit and nurses.

The access points allow for an asynchronous interaction between the mobile unit and nurses - so that both parties can execute their tasks in whatever order or at a point in time that fit them best. Through a smart queue, the mobile units can prioritize tasks based on urgency - ensuring a critical medicine or sample will be delivered first and restocking a supply of tissues after.

This also enables nurses to place item orders through any of the access points, which the next time they visit that patient, they will only have to pick out from the Letterbox rather than running to fetch from a potentially distant storage room.

The access points allow for an asynchronous interaction between the mobile unit and nurses - so that both parties can execute their tasks in whatever order or at a point in time that fit them best. Through a smart queue, the mobile units can prioritize tasks based on urgency - ensuring a critical medicine or sample will be delivered first and restocking a supply of tissues after.

This also enables nurses to place item orders through any of the access points, which the next time they visit that patient, they will only have to pick out from the Letterbox rather than running to fetch from a potentially distant storage room.

↑ The wheels are mounted far outwards of the footprint, to generate as much stability as possible. The open wheel arch allows to access and clean the omni-directional wheels.

↑ The different elements coming together in the main body are designed to meet in integrated shapes, allowing for easy cleaning by creating no undercuts.

↑ All moveable parts of the manipulator always pivot on blended shapes with generous spacing between each element of the arm, ensuring zero risk of pinch.

Managing Larger Fleet Sizes

ID tags have been introduced to make distinguishing robots in a larger fleet easier. Depending on their assigned tasks and station, the mobile units carry different names and colors. In future scenarios, this concept could scale with more responsibilities, such as delivering food or cleaning out trash.

Fits like a glove!

A silicone cover protects the actuators of the gripper and provides much better cleanability than an approach with exposed actuators. Similarly to how a human would change out a glove after a particular time, the silicone cover could be exchanged during regular maintenance.

Ward Storage

The storage boxes used in wards today have been optimized and redesigned to work efficiently for the autonomous re-supply.

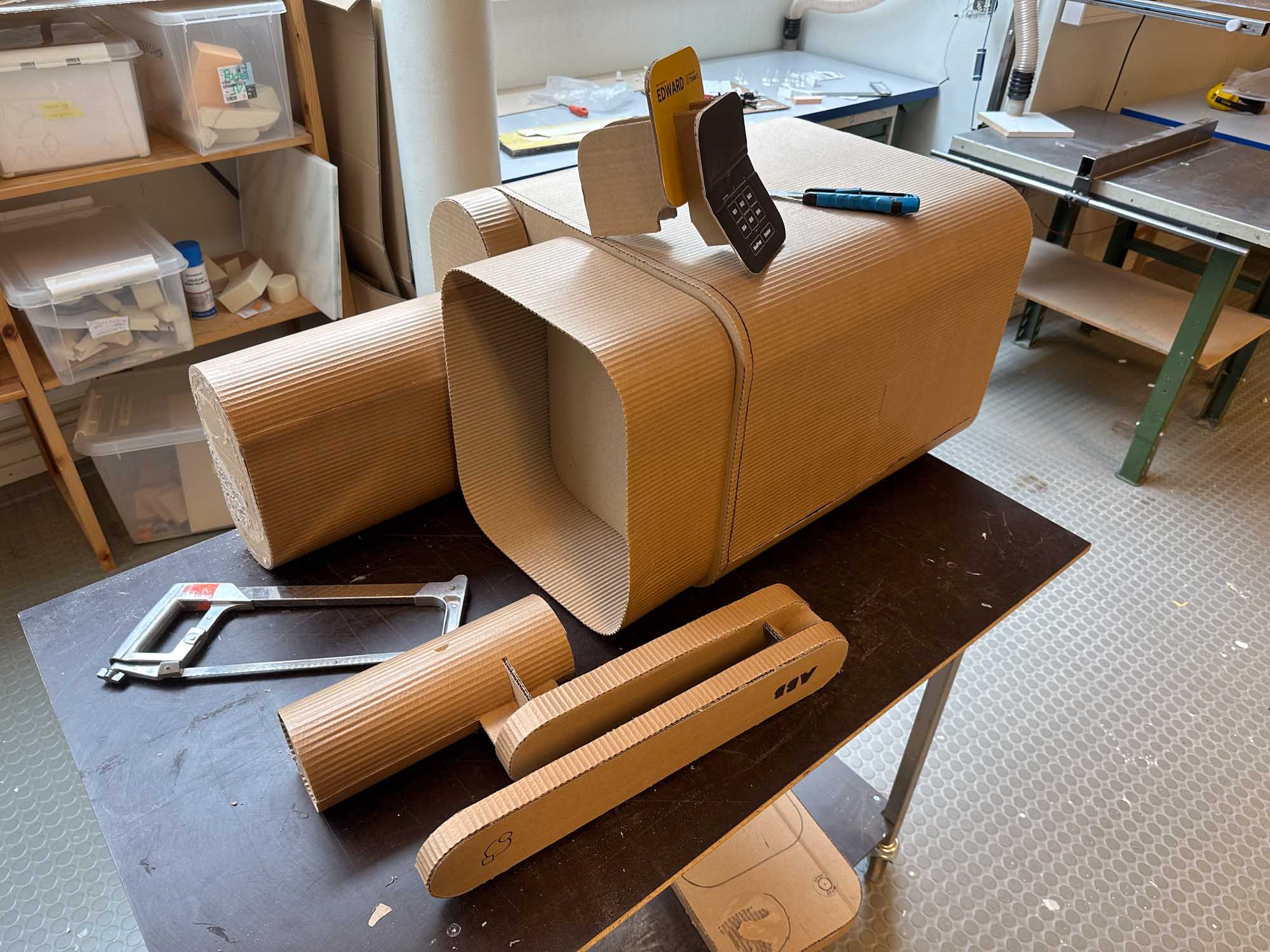

One-to-one scale testing

Due to the scale of the proposed solution, working in full scale has been an essential part to the product development during this project. Early on, tape-drawings have been used to test and validate solutions regarding ergonomics and perception, in the design of a mobile, collaborative robot. Later in the process, quick sketch-models and higher-fidelity cardboard models have been used to simulate solutions in volume, which proved critical to design for an approachable solution.